What Is Electropolishing? The Electropolishing process streamlines the microscopic surface of a metal object using an electrochemical process to remove metal from the object’s surface. This process is similar to, but the reverse of, electroplating. The process sheds the metal peaks (high points) of the treated surface. Our Electropolish Facilities International Corrosion Services’ electropolish bath

What Is Electropolishing?

The Electropolishing process streamlines the microscopic surface of a metal object using an electrochemical process to remove metal from the object’s surface. This process is similar to, but the reverse of, electroplating.

The process sheds the metal peaks (high points) of the treated surface.

Our Electropolish Facilities

International Corrosion Services’ electropolish bath is the largest available in Western Australia. Its capabilities include:

- 5000amp state of the art German manufactured rectifier

- Mixer for agitation of the fluid

- Temperature sensor

- Electrical heaters

- Electrical control panel and control units

- Bath cover/lid (manual handling)

- Fumes exhaust system

- Waste Disposal and recycling system

- 10 tonne and 5 tonne overhead cranes

Our electropolish bath can process stainless steel to the following dimensions:

- 6.5m long, 1.5m deep and 1.3m wide

For larger pieces, we are able to process these using a ‘double dip method’. This method may result in a slight demarcation line if there is an overlap.

All stainless steel processed by ICS is guaranteed to be free of cross-contamination, as we exclusively treat stainless steel. All pieces are moved using soft slings, guaranteeing no scratches or damage.

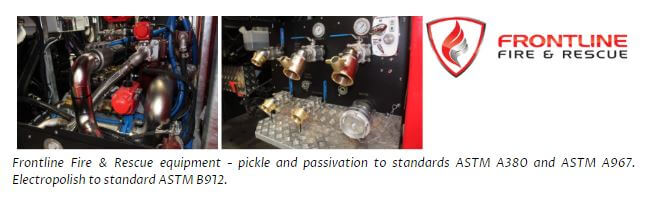

Our electropolish bath complies to Standards ASTM B912 and ASTM A1380.

What Are The Benefits of Electropolishing?

Electropolishing offers a range of benefits to your stainless steel, including better physical appearance, enhanced mechanical properties and better corrosion resistance.

Electropolishing also provides a smooth, clean surface which is easier to sterilise and is able to polish areas which may be inaccessible using other methods.

Additionally, electropolishing offers a range of benefits across industries.

Hospitality

Electropolishing can offer the Hospitality industry numerous benefits, including:

- Reduces the likelihood of food contamination

- Improves equipment hygiene

- Reduces the potential of equipment harboring bacteria

- Resists bacteria and moisture, providing a safer surface for both food and drink processing equipment

Marine

Electropolishing can offer the Marine industry numerous benefits, including:

- Improved corrosion resistance and rust protection

- A clean, smooth finish

- Extension of life – especially critical due to the the harsh environment marine equipment is exposed to

Medical

Electropolishing can offer the Medical industry numerous benefits, including reducing the risk of the following:

- Implant rejection

- Bio-incompatibility

- The spread of pathogens

- Premature failure

- Contamination

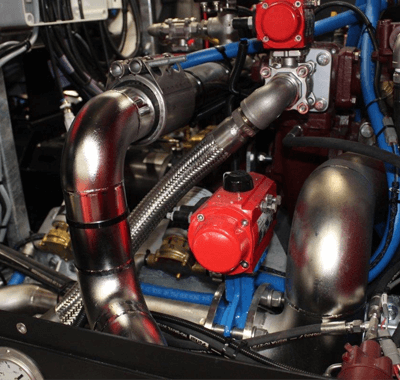

Examples of Electropolishing Works

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023

ICS will be closed for the Christmas and New Year period from 12pm, 22 Dec - 9 Jan 2023